SERVICES AND CAPABILITIES

The Research and Instructional Support Facility (RISF) provides machining, technical design and consulting services to the College of Science and Technology and Temple University researchers. A student machine shop located adjacent to the main facility allows students to use basic shop tools to support their work after taking a required shop introduction and safety program.

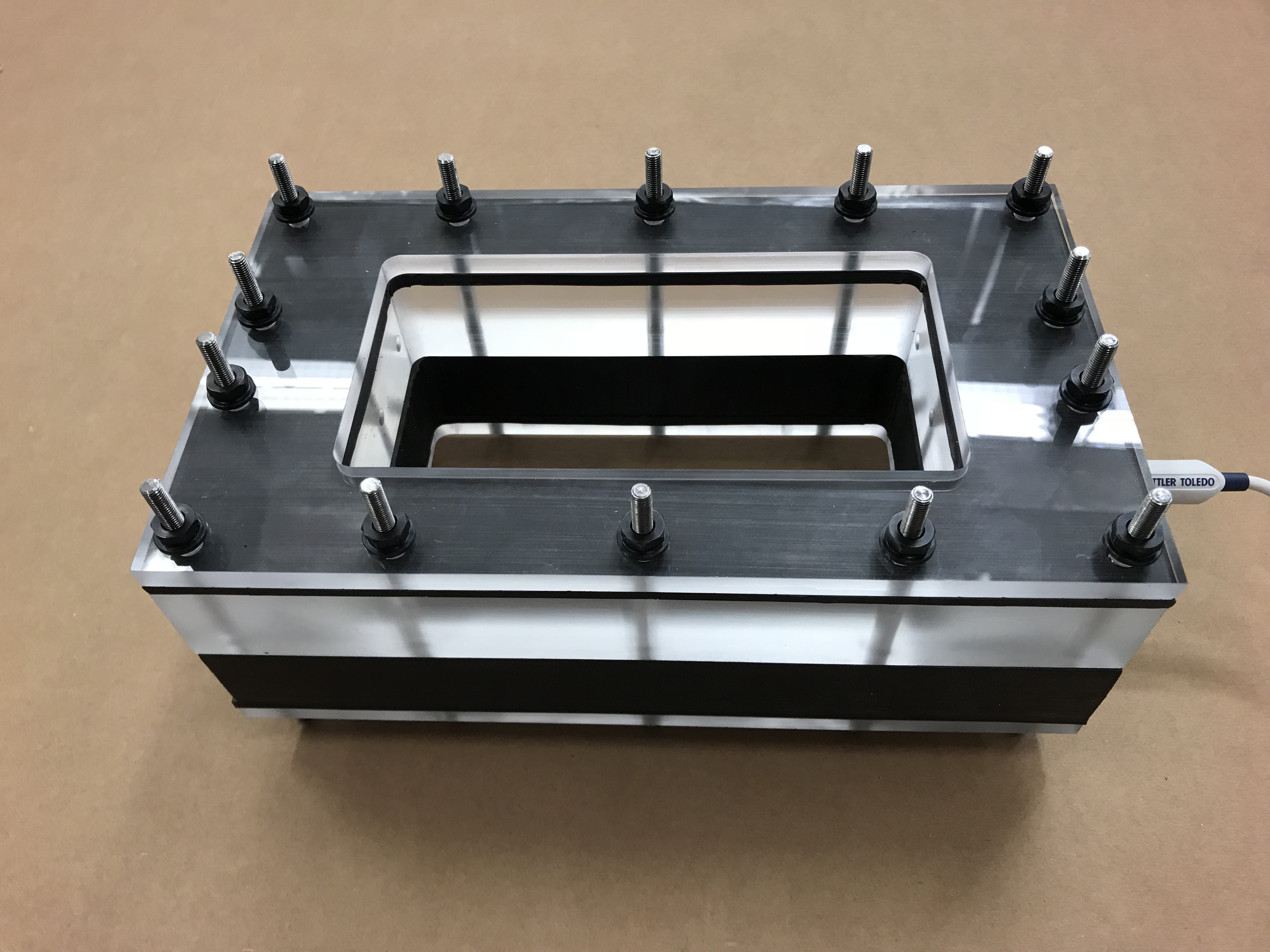

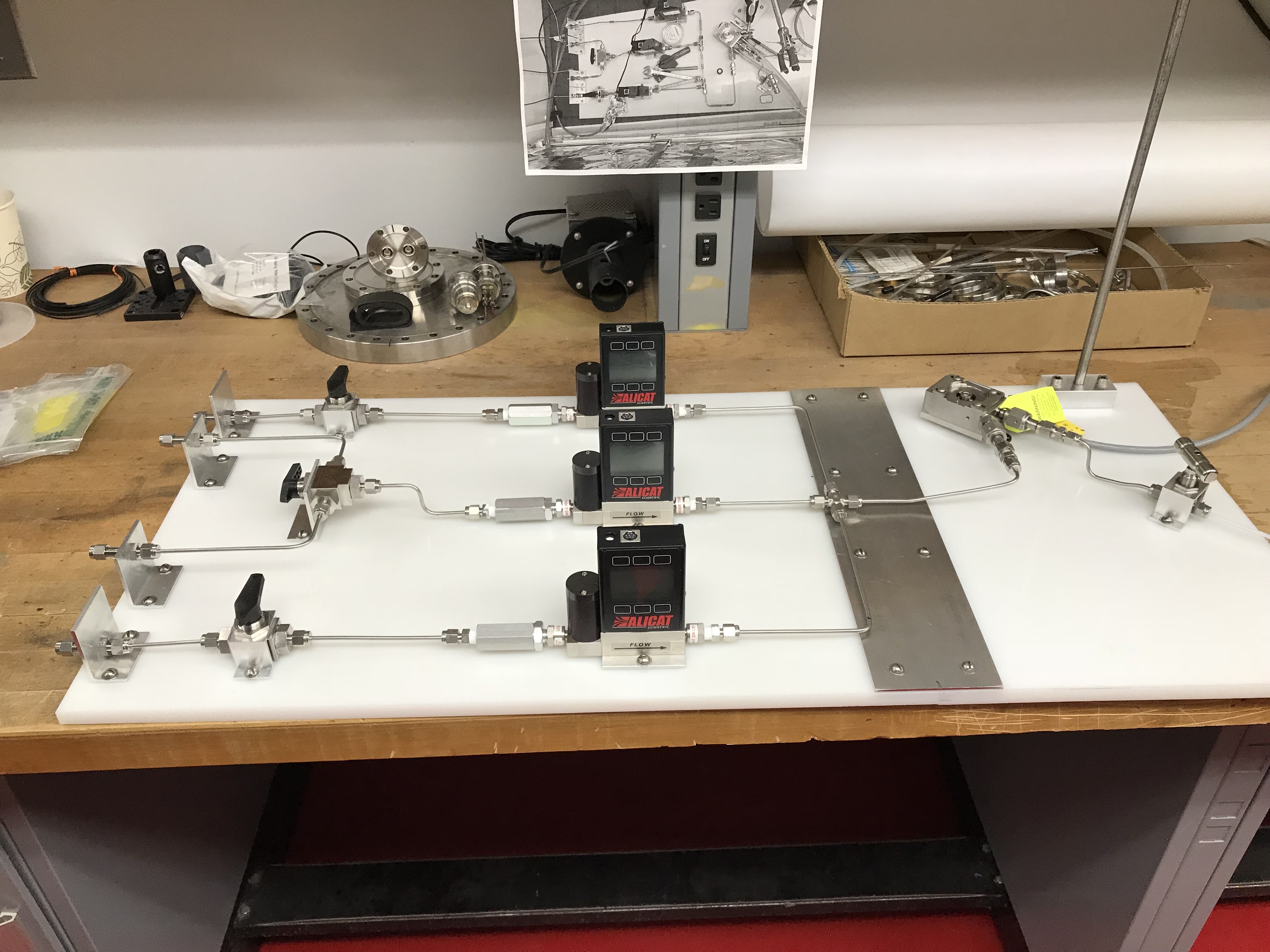

Metal Fabrication

Capabilities include milling, lathe turning, and surface grinding of typical metals including aluminum, brass, stainless steels and other metal alloys.

Welding, Brazing and Soldering

Welding of metals like aluminum and stainless steel for both structural purposes and leak tight vacuum or pressure vessels. “Soft or hard” soldering of stainless steel, copper, brass and other cupreous metals.

Plastics and other non-metals

Machining of acrylics and other types of polymers. Custom made or modified fabricated parts can be joined by either solvent welding or hot-air ‘fusion’ for liquid and air tight seal.

Charges and Authorization

The labor charge is $55 dollars an hour for work done by a facility staff member. Before proceeding with work, a cost center account number must be provided and a signed authorization is required from a budget unit head or principal investigator.